Industrial manufacturing processes often produce plastic waste from trimmings, color changeovers, purging, and manufacturing defects during production. Plastic tolling helps to minimize this waste by reusing and recovering the plastic scrap through grinding, cleaning, compounding, and pelletizing the industrial waste polyethylene plastics. By outsourcing this process, manufacturers can be more efficient with their materials, reduce production costs, and increase sustainability.

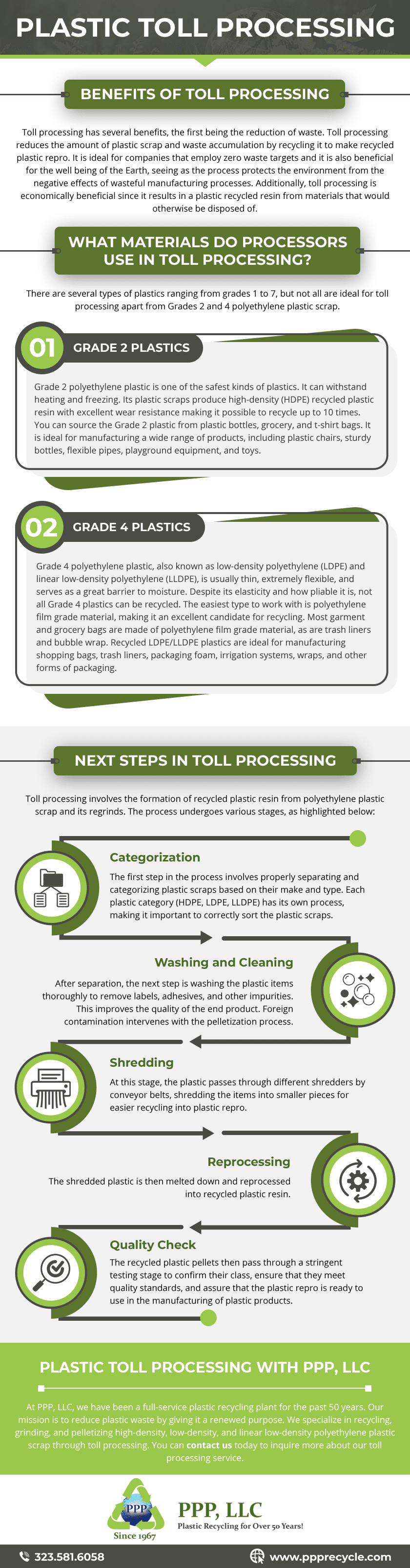

Benefits of Toll Processing

Toll processing has several benefits, the first being the reduction of waste. Toll processing reduces the amount of plastic scrap and waste accumulation by recycling them to make recycled plastic repro. It is ideal for companies that employ zero waste targets and it is also beneficial for the well being of the Earth, seeing as the process protects the environment from the negative effects of wasteful manufacturing processes. Additionally, toll processing helps save money by creating a plastic recycled resin from materials that would otherwise be disposed of.

What Materials Do Processors Use in Toll Processing?

There are several types of plastics ranging from grades 1 to 7, but not all are ideal for toll processing apart from Grades 2 and 4 polyethylene plastic scrap.

Grade 2 Plastics

Grade 2 polyethylene plastic is one of the safest kinds of plastics. It can withstand heating and freezing. Its plastic scraps produce high-density (HDPE) recycled plastic resin with excellent wear resistance making it possible to recycle up to 10 times. You can source the Grade 2 plastic from plastic bottles, grocery, and t-shirt bags. It is ideal for manufacturing a wide range of products, including plastic chairs, sturdy bottles, flexible pipes, playground equipment, and toys.

Grade 4 Plastics

Grade 4 polyethylene plastic, also known as low-density polyethylene (LDPE) and linear low-density polyethylene (LLDPE), produces low-density recycled plastic resin. Many manufacturing plants consider it safe for use, but only a small percentage of Grade 4 plastics can be recycled. The most elastic and manageable Grade 4 plastic to work with is any polyethylene film grade material. A good source of this plastic is garment bags, trash liners, and bubble wrap. LDPE/LLDPE plastics are ideal for shopping bags, packaging foam, irrigation systems, squeezable bottles, trays, containers, and other plastic molds and wraps.

Next Steps in Toll Processing

Toll processing involves the formation of recycled plastic resin from polyethylene plastic scrap and its regrinds. The process undergoes various stages, as highlighted below:

- Categorization: The first step in the process involves properly separating and categorizing plastic scraps based on their make and type. Each plastic category (HDPE, LDPE, LLDPE) has its own process, making it important to correctly sort the plastic scraps.

- Washing and Cleaning: After separation, the next step is washing the plastic items thoroughly to remove labels, adhesives, and other impurities. This improves the quality of the end product. Foreign contamination intervenes with the pelletization process.

- Shredding: At this stage, the plastic passes through different shredders by conveyor belts, shredding the items into smaller pieces for easier recycling into plastic repro.

- Reprocessing: The shredded plastic is then melted down and reprocessed into recycled plastic resin.

- Quality Check: The recycled plastic pellets then pass through a stringent testing stage to confirm their class, ensure that they meet quality standards, and assure that the plastic repro is ready to use in the manufacturing of plastic products.

Plastic Toll Processing with PPP, LLC

At PPP, LLC, we have been a full-service plastic recycling plant for the past 50 years. Our mission is to reduce plastic waste by giving it a renewed purpose. We specialize in recycling, grinding, and pelletizing high-density, low-density, and linear low-density polyethylene plastic scrap through toll processing. You can contact us today to inquire more about our toll processing service.