The plastic industries are unquestionably significant in producing products, parts, and components that people frequently use. However, the consequences of plastic manufacturing, consumption, and disposal are becoming increasingly alarming. For instance, the non-biodegradable property of plastic materials poses a concern to the ecosystem as it causes contamination and pollution.

At PPP, LLC, we partner with our customers to reduce waste by repurposing used plastics in the supply chain. We provide plastic reprocessing from start to finish, producing high-quality plastic repro pellets.

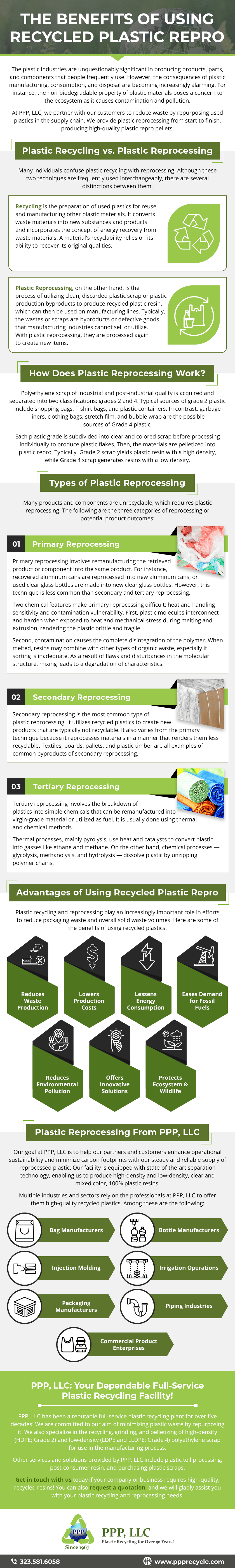

Plastic Recycling vs. Plastic Reprocessing

Many individuals confuse plastic recycling with reprocessing. Although these two techniques are frequently used interchangeably, there are several distinctions between them.

Recycling is the preparation of used plastics for reuse and manufacturing other plastic materials. It converts waste materials into new substances and products and incorporates the concept of energy recovery from waste materials. A material’s recyclability relies on its ability to recover its original qualities.

Plastic reprocessing, on the other hand, is the process of utilizing clean, discarded plastic scrap or plastic production byproducts to produce recycled plastic resin, which can then be used on manufacturing lines. Typically, the wastes or scraps are byproducts or defective goods that manufacturing industries cannot sell or utilize. With plastic reprocessing, they are processed again to create new items.

How Does Plastic Reprocessing Work?

Polyethylene scrap of industrial and post-industrial quality is acquired and separated into two classifications: grades 2 and 4. Typical sources of grade 2 plastic include shopping bags, T-shirt bags, and plastic containers. In contrast, garbage liners, clothing bags, stretch film, and bubble wrap are the possible sources of Grade 4 plastic.

Each plastic grade is subdivided into clear and colored scrap before processing individually to produce plastic flakes. Then, the materials are pelletized into plastic repro. Typically, Grade 2 scrap yields plastic resin with a high density, while Grade 4 scrap generates resins with a low density.

Types of Plastic Reprocessing

Many products and components are unrecyclable, which requires plastic reprocessing. The following are the three categories of reprocessing or potential product outcomes:

Primary Reprocessing

Primary reprocessing involves remanufacturing the retrieved product or component into the same product. For instance, recovered aluminum cans are reprocessed into new aluminum cans, or used clear glass bottles are made into new clear glass bottles. However, this technique is less common than secondary and tertiary reprocessing.

Two chemical features make primary reprocessing difficult: heat and handling sensitivity and contamination vulnerability. First, plastic molecules interconnect and harden when exposed to heat and mechanical stress during melting and extrusion, rendering the plastic brittle and fragile.

Second, contamination causes the complete disintegration of the polymer. When melted, resins may combine with other types of organic waste, especially if sorting is inadequate. As a result of flaws and disturbances in the molecular structure, mixing leads to a degradation of characteristics.

Secondary Reprocessing

Secondary reprocessing is the most common type of plastic reprocessing. It utilizes recycled plastics to create new products that are typically not recyclable. It also varies from the primary technique because it reprocesses materials in a manner that renders them less recyclable. Textiles, boards, pallets, and plastic timber are all examples of common byproducts of secondary reprocessing.

Tertiary Reprocessing

Tertiary reprocessing involves the breakdown of plastics into simple chemicals that can be remanufactured into virgin-grade material or utilized as fuel. It is usually done using thermal and chemical methods.

Thermal processes, mainly pyrolysis, use heat and catalysts to convert plastic into gasses like ethane and methane. On the other hand, chemical processes — glycolysis, methanolysis, and hydrolysis — dissolve plastic by unzipping polymer chains.

Advantages of Using Recycled Plastic Repro

Plastic recycling and reprocessing play an increasingly important role in efforts to reduce packaging waste and overall solid waste volumes. Here are some of the benefits of using recycled plastics:

Reduces Waste Production

Recycled and reprocessed plastics decrease the amount of plastic that ends up in landfills by increasing the durability of plastic in practical applications. Furthermore, plastic recycling lowers the necessity to generate fresh raw resources by reusing already processed materials. This results in natural resource conservation and lower emissions of greenhouse gasses that trap heat in the atmosphere.

Lowers Production Costs

Using recycled plastic minimizes variable production costs since repurposed resin is significantly cheaper than new material. Furthermore, recent plastic processing technologies can produce plastic with comparable qualities as their virgin equivalent, frequently at a more affordable cost.

Lessens Energy Consumption

Extracting and processing raw materials into useful plastic materials and products requires substantial energy. In contrast, recycling conserves energy since recycled plastics require far less processing to become useful resources.

Eases Demand for Fossil Fuels

Each year, millions of crude oil barrels are used to support the need for plastics. However, several studies found that recycling plastics is the most efficient alternative to reduce the usage of fossil fuels. Consequently, the recycling and reprocessing methods can significantly cut crude oil consumption.

Reduces Environmental Pollution

Greenhouse gases are a major factor in increasing environmental pollution — they are the main force behind climate change, a critical problem that the world is currently attempting to address. To help alleviate pollution, recycling plastic instead of producing it from scratch effectively minimizes the emission of harmful gasses. Moreover, using recycled plastic repro reduces the volume of plastic waste.

Offers Innovative Solutions

Manufacturers use recycled plastic to make appealing and useful products, including textiles, containers, accessories, bags, and car components. The inventiveness that manufacturers can apply to discarded plastic is also limitless and well worth exploring.

Protects Ecosystem and Wildlife

Recycling plastics is one of the most effective means of protecting the natural environment and wildlife. However, plastic deposited in the oceans harms aquatic life because some of it is ingested by marine organisms. The same applies to animals on land, particularly domesticated animals in metropolitan areas.

According to the sources available, countless marine species and creatures perish each year due to their absorption of plastic and water-borne contaminants. This is equally hazardous to humans and animals drinking contaminated water.

Plastic Reprocessing From PPP, LLC

Our goal at PPP, LLC is to help our partners and customers enhance operational sustainability and minimize carbon footprints with our steady and reliable supply of reprocessed plastic. Our facility is equipped with state-of-the-art separation technology, enabling us to produce high-density and low-density, clear and mixed color, 100% plastic resins.

Multiple industries and sectors rely on the professionals at PPP, LLC to offer them high-quality recycled plastics. Among these are the following:

- Bag manufacturers

- Bottle manufacturers

- Commercial product enterprises

- Injection molding

- Irrigation operations

- Packaging manufacturers

- Piping industries

PPP, LLC: Your Dependable Full-Service Plastic Recycling Facility!

PPP, LLC has been a reputable full-service plastic recycling plant for over five decades! We are committed to our aim of minimizing plastic waste by repurposing it. We also specialize in the recycling, grinding, and pelletizing of high-density (HDPE; Grade 2) and low-density (LDPE and LLDPE; Grade 4) polyethylene scrap for use in the manufacturing process.

Other services and solutions provided by PPP, LLC include plastic toll processing, post-consumer resin, and purchasing plastic scraps.

Get in touch with us today if your company or business requires high-quality, recycled resins! You can also request a quotation, and we will gladly assist you with your plastic recycling and reprocessing needs.